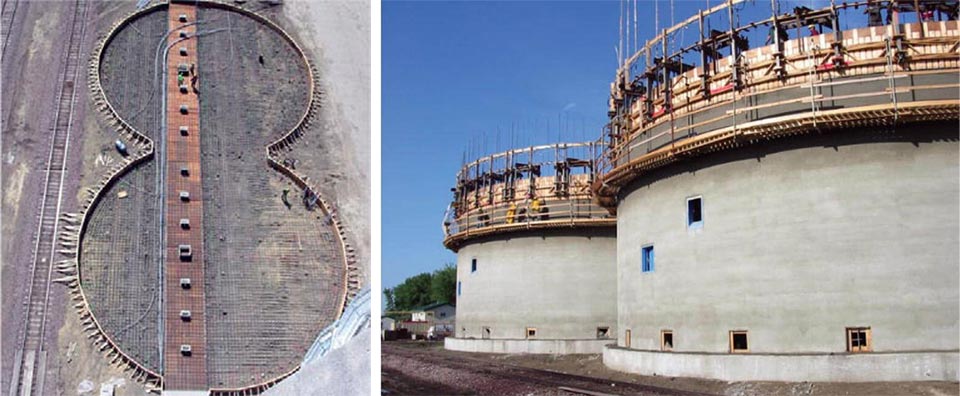

Casselton Terminal Construction

On April 16, 2004, Vigen Construction started construction on the Casselton Shuttle Loading Terminal. This initial project had many components. Included in this project was: • 3 – 290,000 Bushel Concrete Tanks • Track Expansion to Accommodate 120 Rail Cars • Rail Unloading Pit • Rail Load Out System • 3 – 30,000 bu/hr. Legs • 120,000 lb. scale • 2 – 20,000 bu/hr. Dump Pits. • The Casselton Terminal was fully operational in April of 2005.

Office Building Construction

In February 2005 Diamond Home Construction built the Office in Casselton. The two story office is 42 feet wide by 52 feet long. The building had 10 offices and a conference/ lunch room along with a grain inspection lab.

Casselton Dryer Construction

In September of 2005, Vigen Construction Erected a 4,500 bu/hr GSI Tower Dryer on the north side of the old AGP Elevator. Along with the dryer there was a 10,000 bu/hr wet leg and a 10,000 bu/hr dry leg included in this project.

Eagan Land Purchase

Maple River Grain & Agronomy’s vision to centralize in Casselton would not have come together without the purchase of 21.48 acres from Marlys Eagan in 2006. The land was located to the east of the railroad tracks which now house our fertilizer, chemical, and soon to be storage shed. After much persistence and negotiation by Sid Mauch an agreement was reached. At the time of purchase the price seemed high but now that we look back on the development of those acres it was well worth the cost.

Locomotive Shed

In 2008 Foltz Construction erected a 20 foot by 80 foot shed for our locomotive. This heated shed allows us to keep a locomotive on site during the winter even on the coldest days.

Fertilizer Plant Construction

In April of 2008, Marcus Construction broke ground on a 38,000 Ton Dry Fertilizer Plant. This project was completed in January of 2009. Included in this project was: 170 ft by 320 ft 8 Bin Fertilizer Warehouse 1,200 Ton/hr. Rail Car Unloading Pit 2 – 250 Ton/hr. Load Out Legs 2 – 200 Ton Fertilizer Towers 2 – 14 Ton Fertilizer Blenders

Casselton Terminal Expansion

In the spring of 2010 Vigen Construction started construction of more grain storage and a new dryer for the Casselton Terminal. The project was complete in October of 2010. Included in this project was: • 2 – 500,000 bu Concrete Bins • 10,000 bu/hr Zimmerman Grain Dryer • 2 – 20,000 bu Legs for the Dryer • Outbound Truck Scale and Automated Truck Receiving Software

Chemical/Seed Warehouse and Shop

In April of 2011, Marcus Construction started construction of a 120 ft wide by 400 ft long Chemical/Seed Warehouse and Shop. The entire building is heated with in floor water heat. There is also an automated fire protection sprinkler system through the whole building. The project was completed in February of 2012. Included in this project was: • Shop, Vehicle Wash Bay and Oil Change Pit • Seed/Chemical Warehouse with 2 Loading Docks • Bulk Chemical Warehouse with Drive Through Loading Bay

Peak Purchase

In July of 2011 Maple River Grain and Agronomy, LLC started leasing the Peak Elevator from HiLine Farmers Elevator. The facility is located 3 miles East of Valley City. The Peak Elevator has 765,000 bu of grain storage. In January 2013 MRGA purchased the facility.

Applicator Upgrades

Demand for application services prompted a 3-year plan to upgrade all application equipment starting in 2011. That year the Board of Directors agreed to purchase one dry floater, one liquid floater, and one sprayer. In 2012 two terragators and one rogator were purchased and in 2013 one terragator and two sprayers were purchased. These upgrades allowed more acres to be covered in a shorter period.

Seed Treater and Bulk Seed Bins

In February of 2012 Hamilton Systems began construction of the Seed Treater attached to the chemical and seed warehouse. The seed treater can treat 2000 units an hour. The computer controlled bulk weigher allows for continuous flow of seed. The treater was integrated with 11 bulk hopper bins and also can treat seed out of totes. In 2014 Maple River Grain and Agronomy, LLC added 6 more bulk hopper bins.

AnyConnect Wireless Purchase

We have strived to be the leader in technology. All our locations were wirelessly connected in 2007. In 2012 we had the opportunity to purchase that technology. This purchase secured our VPN and gave us an opportunity to help our rural patrons receive higher speed internet. Since that purchase, we have put many dollars into upgrades, new towers, and more bandwidth. This month we were excited to launch Maple River Communications with a goal to better service rural America.

Bulk Chemical Automation System

In February 2013, Murray Systems installed 13 chemical tanks with meters. This allows us to fill patron’s bulk chemical tanks with accuracy to a tenth of a gallon. It also allows real time inventory and billing.

Peak Scale Construction

In June of 2013 Specialty Products started construction of a 12 foot by 116 foot outside pit scale. The previous scale in the Peak elevator was 32 feet long and required semis to be split weighed. The scale was completed in September of 2013.

Grandin Facility

Wischer Aviation is an aerial spraying company along with ground application services in Grandin, ND. MRGA, LLC was presented the opportunity to purchase rolling stock and lease their agronomy facility. The partnership has provided the opportunity to extend our customer base north of Prosper.

Flat Grain Storage Building

In December 2013, Marcus Construction broke ground on a flat grain storage building. The building is 300 feet wide by 450 feet long and will hold 4 million bushels of corn. The building is attached to the existing terminal and will fill and reclaim at 60,000 bushels per hour. Along with this building Vigen Construction is adding additional screening capacity in the terminal to accommodate this new storage. The project was completed in the fall of 2014.

Maple River Communications Sale

MRC was sold to Invismax, Inc. – a wireless broadband internet company who services customers throughout MN and ND in December 2016

Circle Piler Project

The location of the circle piler is to the north side of the flat storage shed in Casselton, ND. The circle piler is attached to the elevator and has conveyors that run across the railroad tracks to fill it. Diameter 320 ft. Holds just under 2 million bushels of grain.

Liquid Fertilizer Plant Addition

This project, started in September 2017, involved adding 1800 ton fertilizer capacity to the north of the agronomy warehouse in Casselton. This project included the addition of the below: Loading bay onto the chemical warehouse with (8) 40,000 gal tanks for liquid fertilizer along with (3) 10,000 gal tanks for micronutrients. Fully automated system that allows for multiple tanks to receive truck loaded product and custom blend product to order.

Maple River Co-Op Formed

Chaffee-Lynchburg and Prosper Farmers Co-op Elevator merge to form Maple River Co-op, which owns 71.30% of Maple River Grain & Agronomy LLC.

Technology Advancements

We hired Bryan Trosen as the IT Manager responsible for planning, implementing and maintaining the IT infrastructure for MRGA. Some of the updated projects have been: • New digital phone system. • Server room updates and additional storage. • Moved from physical server to hosted services. • New front door access system. • Transitioning to a web-based software program. • App and webpage updates.

Technology Advancements

Also in June, we hired Ethan Kyllo as the Precision Ag Manager. He is responsible for providing key top agricultural services to customer including: • Mapping • Zone soil sampling • Variable rate mapping • Prescription creation for fertilizer and seed needs • Technological advancement tools like Climate Fieldview and Winfield United R7 Tool

Liquid UAN Tank

This project included the construction of a 2,000,000 gal UAN liquid tank located to the east of the flat grain storage shed in Casselton, ND. Plus: Tank-in-tank containment system Ability to rail in up to 90 cars of 32%, cut to 28% due to ND weather. Complements our current liquid facility. Provides a competitive advantage of rail versus trucking. Unmanned 24/7 cardtrol system. Ability to add ATS to the load through piping from our existing 8 retail blending tanks.

Leased Valley Ag Partners

Effective January 1st, 2020, MRGA started operating the Valley Ag Partners locations in Minnesota. This venture added five new MRGA locations with a mix of grain and agronomy services and many new employees. These new locations are in Barnesville, Dilworth, Kragnes, Rothsay, and Sabin.